EPIRB Servicing

What’s involved in an EPIRB service?

Visual Examination and Initial Testing

The EPIRB is given an initial checkover, and a full radiated test is performed to verify correct transmission on 406MHz and 121.5MHz.

We don’t rely on the EPIRB’s self-test function, but we use a special purpose beacon tester to check out the frequency, power, and coding.

If there is any problem at this stage, then it is likely that repair work may be needed, in addition to routine servicing. It may not be worth continuing with the service, particularly if the beacon is an older model.

We will contact the owner to explain the options before incurring any further expense.

If all is well, the details will be entered into our in-house designed “EPIRB Service Assistant” – software which guides the operator through the service process for each EPIRB type and documents the work carried out and parts fitted.

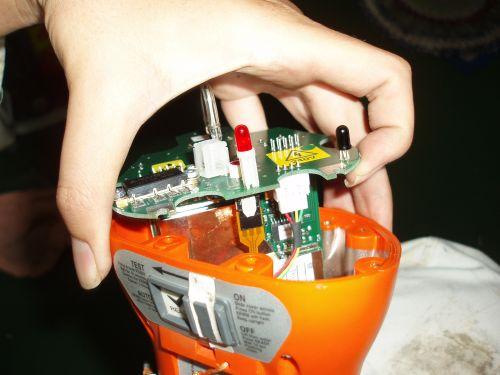

Disassembly

Some EPIRBs are not designed for easy service! Often the battery is in the bottom of the case, so everything has come out first.

Replacement of service parts

As a minimum, this will involve fitting a new primary lithium battery pack, however there are usually O-rings, gaskets, silicagel and sometimes special screws with integral seals that need to be replaced.

Some manufacturers (e.g. GME) provide a new antenna and a complete set of case mouldings with their service kits, so the serviced beacon is all new except for the circuit board.

In some cases, internal tests may need to be carried out. For instance, the manufacturer may advise continuous power tests by putting the beacon into a special test mode, and connecting the transmitter output direct to a power meter.

The EPIRB is then reassembled ready for final testing.

Live transmission test

The only way to be sure that an EPIRB will work in an emergency is to activate it – but the satellite system is very sensitive, and false alerts must be avoided! We test all EPIRBs in a radio screened box using the Faraday Cage principle to prevent any significant radiation of the distress signal. Depending on the beacon type, the EPIRB may be activated by using the manual “ON” setting, or by floating in a container of water to activate the seawater contacts.

A “sniffer” antenna inside the box connects to an external test receiver to decode the transmitted signal.

Of course, placing the EPIRB inside a screened box ensures that no GPS signals penetrate, so in order to enable GPS equipped EPIRBs to be tested, we fit our screened box with a GPS repeating system. The signal from an externally mounted GPS antenna is amplified and fed into the box so that the EPIRB can acquire and transmit its position to the external receiver.

Leak testing

EPIRBs are designed to be waterproof up to a depth of 10m (+1 bar). If seals are not correctly fitted and seated, then water may get in during storage, and salt water will very soon wreck the electronics. So all EPIRBs need to be pressure tested after reassembly. The EPIRB is fully immersed in a sink full of hot water (minimum 40degC). The air inside the EPIRB heats up and expands, putting positive pressure on the gaskets and seals. Any leaks are easy to see, in the form of a stream of escaping bubbles.

Note that the EPIRB is immersed in a mounting bracket. This disables the seawater contacts to stop the EPIRB from auto activating,

Programming

Most EPIRBs are programmed using an optical interface to a PC. Even if the prgramming details do not need to be changed, there may be internal registers that must be reset, so the EPIRBs knows it has a fresh battery. Otherwise it may fail self-test prematurely.

Labelling

The EPIRB is then clearly labelled to show the the new battery expiry date, plus our name and contact details with the service reference code. This means if there is any question in the future about operation of the beacon, and who changed the battery, you will know who to call. Do not trust anyone who will not put their name to their work.

Registration

We are working with the UK Distress and Security Beacon Registry to try to verify registration data. Within the constraints of the Data Protection Act, we share information on beacon registration to try to ensure that the records held for assistance in SAR operations are as complete and up to date as possible. We provide monthly spreadsheets showing details of all UK coded beacons supplied or serviced. Where possible, we obtain the registered details of beacons with us for service, and check these with the owner to make sure contact details are up to date.

Paperwork

Each serviced EPIRB is despatched with a test summary from our EPIRB Service Assistant software. Also a test certificate showing that all parameters were fully tested